Product

TURNING SCARCITY INTO ABUNDANCE

Unlock peak efficiency with our advanced technology

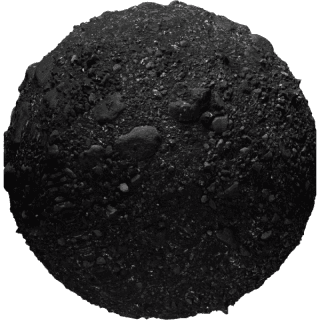

Ekosh Energy's unique process regenerates battery-grade materials such as lithium, cobalt, manganese, and nickel, enabling their reintroduction into the supply chain for lithium-ion cell manufacturing. This approach fosters a local supply of raw materials, significantly reducing the carbon footprint. By advancing recycling technologies, we offer comprehensive closed-loop solutions for managing the entire battery life cycle. at Ekosh we have establisheed an efficient recycling system that spans both the upstream and downstream sectors of the industry.

FROM LACK TO LIMITLESS

We unlock the power of abundance in every challenge

3

6.94

Lithium

Li

27

58.933

Cobalt

Co

28

58.69

Nickel

Ni

25

54.938

Manganese

Mn

Cathode Active Material

CAM

29

63.546

Copper

Cu

Aluminum

Al

13

26.98

Graphite

C

6

12.011